With biological production systems, reproducibility is certainly a virtue. But there is more: Process robustness! Always aim for processes that can take shocks but still give you what you want at the end. Less failed batches, less stress, more reliable production.

Denis Groleau, Adjunct Professor, Faculty of Engineering,

University of Sherbrooke and biotech consultant

Consistency between production batches isn’t a “nice to have.” It’s a baseline requirement for building trust, managing supply chains, and scaling innovation into market-ready reality.

When a good batch isn’t good enough

A product that performs once, in a single trial or production run, is a prototype, not a solution.

Inconsistent batches create risk at every level:

- Field data becomes unreliable.

- Client confidence erodes.

- Regulatory approvals become harder to defend.

- Formulation or logistics must be adjusted batch-by-batch.

In short: without reproducibility, performance cannot be trusted.

And yet, reproducibility remains one of the most overlooked challenges in microbial manufacturing.

Why reproducibility breaks down

Microbial systems are sensitive by nature. Even small, undocumented changes in fermentation, downstream processing, or formulation conditions can impact the biological profile of a product.

Common sources of drift include:

- Subtle variations in oxygenation or nutrient feed rates

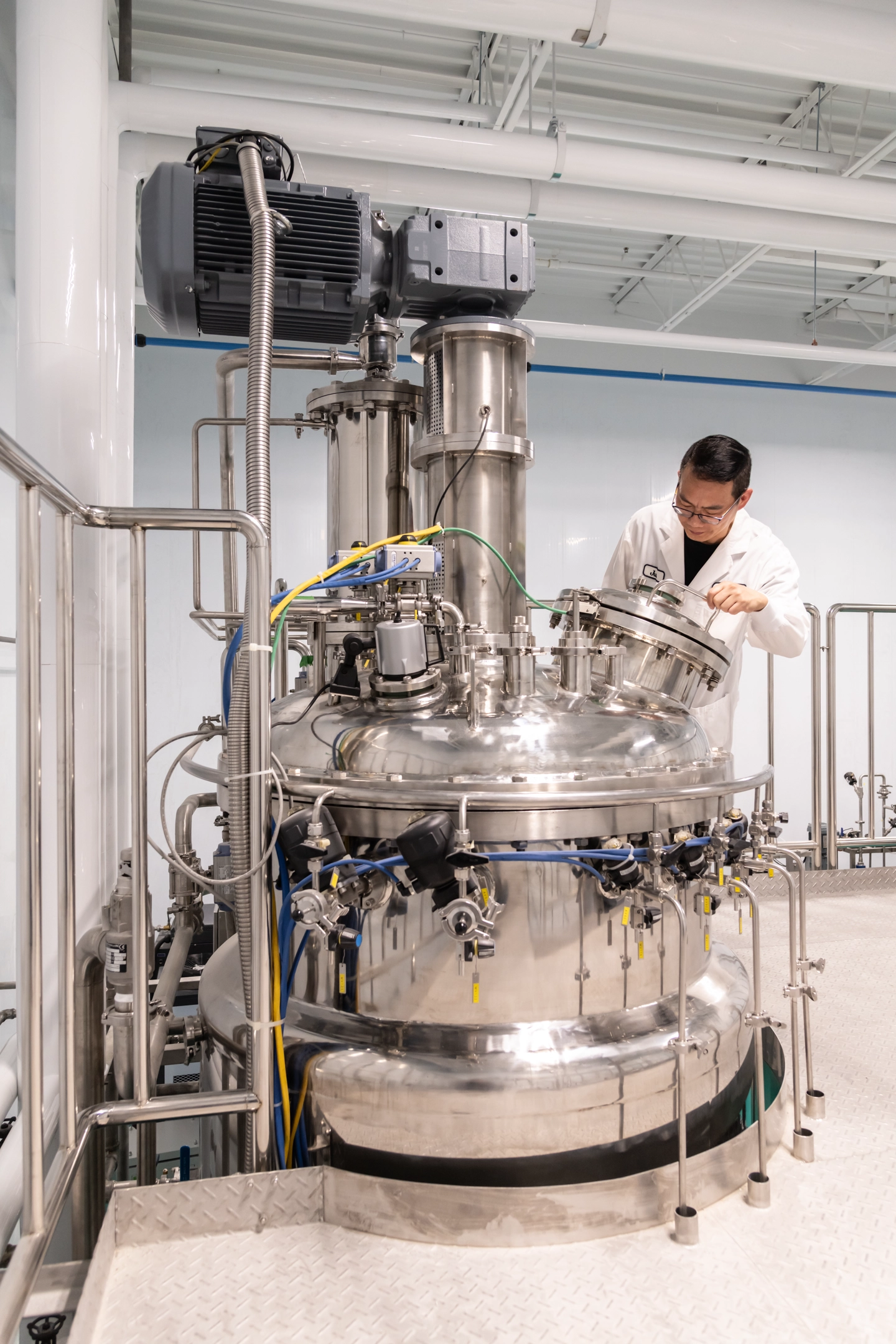

- Scale-up from lab fermenters to industrial bioreactors (2L → 2,000L)

- Inconsistent raw material sourcing or carrier quality

- Manual adjustments made during formulation or drying

- Sensor drift and equipment maintenance issues

- Uneven temperature distribution in larger vessels due to heating or cooling limitations

- Increased contamination risk associated with the cleaning and sterilization challenges of large-scale equipment

These changes may not affect CFU counts or visual appearance but they can profoundly alter strain metabolism, stress tolerance, or field behavior.

Biological products, such as proteins and cells, are quite capricious products. Even if one follows very closely the “production recipe”, full guarantee of the end-product performance is not assured. The biological product will need to face the stress associated with product formulation and its “acceptance” by more or less hostile field conditions. Even the best medicines are not 100% efficacious.

D. Groleau

Designing for consistency: the Proventus Model

At Proventus, reproducibility is engineered into every step of development, from early strain selection to full-scale production. Our goal is simple: every batch must perform like the last one and the next.

Our reproducibility protocol includes:

- Industrial-scale fermentation modeling

We anticipate the effects of scale-up from day one, testing at multiple volumes and stress levels—not just in R&D-scale conditions. - Process control and documentation

Fermentation parameters are tightly monitored. Deviations are logged, analyzed, and used to refine SOPs for future runs. - Intermediate QA checkpoints

We introduce quality checks at key stages—pre-harvest, post-harvest, pre-formulation—to catch deviations before they become customer-facing issues. - Formulation consistency safeguards

Our formulation workflows are adapted to minimize operator variability, preserve microbial stability, and maintain homogeneity at scale.

Scaling up a microbial process where the cell is the wanted product implies risk at each scale-up step, the riskiest one being the transition from shake flasks to the first small-scale bioreactor. It may go from total failure to 100% success, 70% being quite a promising result. One needs to remain modest: We may think that we are in control of the operations but the cell decides at the end. Scale-up work teaches you humility.

D. Groleau

Why reproducibility builds competitive advantage

In microbial B2B markets, innovation alone is not enough.

Clients want confidence:

- Confidence that today’s batch will match last quarter’s.

- Confidence that regional production can deliver identical performance.

- Confidence that long-term partnerships won’t collapse due to hidden drift.

For distributors and integrators, reproducibility means reduced risk, smoother logistics, and stronger customer retention.

Conclusion: reproducibility is the new standard of robustness

Microbial innovation doesn’t scale unless quality scales with it. At Proventus, batch-to-batch reproducibility isn’t a technical milestone. It’s the foundation of trust internally, operationally, and in-market.

Because in microbial manufacturing, a product isn’t judged by its best batch.

It’s judged by its worst.